UP Vario Bench

The first

MULTIFUNCTIONAL and TRANSPORTABLE

front press brake support

- Do you use hemming tools?

- Do you find it difficult with large sheets?

- Do you want a trolley with wheels that can be transported to all locations?

UP Vario Bench is the solution you are looking for

The innovative support that speeds up and increases performance in sheet metal working

UP Vario Bench is the first multifunctional and transportable front press brake support.

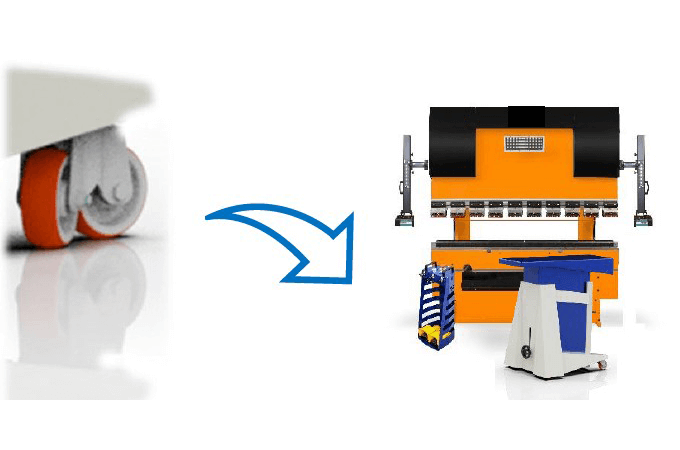

UP Vario Bench stands out from all other press brake front support due to its portability on integrated wheels. The fact that it is transportable makes it easy to move between different workstations and because it is easy to remove and relocate, it is not restricted to use on just one press brake in the company’s fleet.

The design of our support aims at maximum operational flexibility.

WHAT MAKES IT UNIQUE

- Portability on integrated wheels

- Double height adjustment

- Front register displayed

- Laser line generator

- Turntable application

Portability on integrated wheels

Easy to move between different workstations and not tied to the exclusive use of a single press brake in the company's fleet.

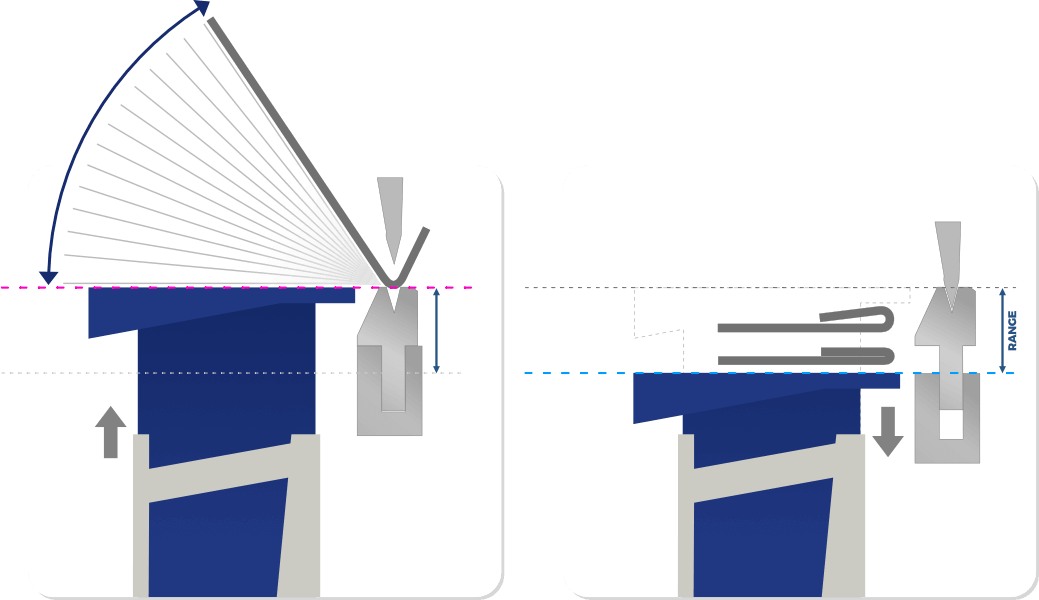

Double height adjustment

Allows precise customisation to the specific needs of the job

• ADJUSTMENT OF DIE HEIGHT from 850 mm to 1100 mm.

• HEIGHT ADJUSTMENT OF THE HEMMING TOOL.

Another manual handwheel and an actuator ensure precise control of the folding and hemming tool. In addition, an electrically-operated vertical movement system enables the set height change to be performed automatically, further improving operating efficiency.

Front register displayed

The UP Vario Bench trolley is equipped with a visualised front register designed for:

• FACILITATING THE POSITIONING of the SHEET METAL to be processed.

• SET THE DESIRED POSITION PRECISELY, ensuring consistent results.

Laser line generator

To further increase accuracy, the UP Vario Bench includes a laser line generator that traces the bending line on the workpiece. This function is essential to ensure that each bend is made exactly at the desired point, reducing errors and avoiding scrap.

Turntable application

Finally, an applicable slewing bearing allows the direction of the workpiece front to be adjusted by 360° smoothly and quickly, offering an additional level of control and precision during the sheet metal bending process.

WATCH NOW

how to perform a hemming tool operation

without and with UP Vario Bench!

UP VARIO BENCH will be presented at the EuroBLECH 2024 exhibition,

where you will be able to see it in action as a world premiere.

For the first 30 pieces available, we are offering it at a unique and unrepeatable LAUNCH PRICE.

Hall 14 - Stand L10

IMPROVE PROCESSING, BENEFIT FROM RESULTS

1.

EASILY TRANSPORTABLE

to

FAST APPLICATION ON SEVERAL MACHINES

Thanks to its wheels, which make it a trolley system, it can be quickly moved from one press to another according to processing needs.

2.

CUSTOMISABLE HEIGHT ADJUSTMENT

to

PERFECT ALIGNMENT AND STABILITY

The double height adjustment with respect to the die and also with respect to the hemming tool will put the sheet exactly where it needs to be.

3.

INTEGRATED PRECISION TOOLS

to

AVOIDANCE OF ERRORS AND REJECTS

The front register with feed rate display, together with the laser line generator for drawing the bending line directly on the sheet metal and the front turntable that fluidly directs the workpiece, are all tools integrated on UP Vario Bench for maximum precision.

to access the exclusive launch promotion

During EuroBLECH 2024 you can see UP Vario Bench in action.

For the first 30 pieces available, we offer a special launch price.

13 of these have already been booked!

Catch this unique opportunity!

Leave your contact details in the form below and we will get back to you shortly.

Triveneta Impianti Srl

Administrative headquarters

Via Scopella 22

37060 Castel d’Azzano VR – Italy

Operational headquarters

Via Bovolino 18/b

37060 Buttapietra VR – Italy

Phone +39 045 518 747

E-mail: info@trivenetaimpianti.com

WWW: trivenetaimpainti.com

Triveneta Impianti Srl

We are specialized in the retrofitting of sheet metal working machines to increase PERFORMANCE and SAFETY, up to saving you the purchase of new machines.