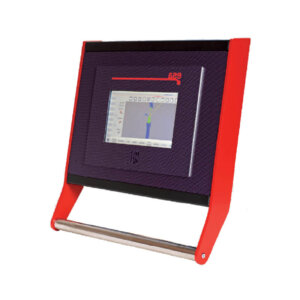

Decisive performance increase of press brakes, folding machines and shears

to make the operator's work easier and more agile, maximizing speed and precision.

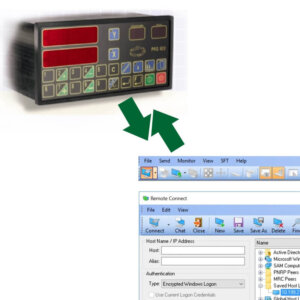

Numerical controls and positioners

Numerical controls are fundamental to sheet metal working, ensuring high control and precision in bending, cutting and other operations.

Numerical controls, in fact, control and manage the very operation of press brakes and shears, as they can be used to programme the machine tool to perform a series of predefined operations, guaranteeing repeatability of machining and precision of results. In addition, the NC allows you to control production process variables such as machining speed, optimising machine efficiency by improving machining times.

PRG programmable positioners, on the other hand, are devices that allow precise and repetitive positioning of the material being processed, offering enormous versatility in application. Overall, PRG programmable positioners are an essential tool for improving productivity and reducing machining errors.

Search

Start writing, wait a few seconds for the results…

Triveneta Impianti Srl

Administrative headquarters

Via Scopella 22

37060 Castel d’Azzano VR – Italy

Operational headquarters

Via Bovolino 18/b

37060 Buttapietra VR – Italy

Phone +39 045 518 747

E-mail: info@trivenetaimpianti.com

WWW: trivenetaimpainti.com

Triveneta Impianti Srl

We are specialized in the retrofitting of sheet metal working machines to increase PERFORMANCE and SAFETY, up to saving you the purchase of new machines.