Based on your needs, which are to be defined during contact with one of our experts in the technical department, as well as the product on which it will be applied, we will determine which encoder is the perfect one to meet your requirements.

Optical encoders are so high-performance that they replace magnetic encoders, which have a lower resolution and are therefore less accurate.

Incremental rotary encoders are often used in machine tools because they allow precise control of the tool position. When the encoder is connected to the tool, it sends a signal that is used by the machine’s numerical control to track the position of the tool in real time.

This allows the machine tool to do precise and repetitive operations without having to be constantly re-positioned by the operator. The application of an incremental rotary encoder therefore improves machine productivity and the quality of the parts produced, reducing positioning and machining errors.

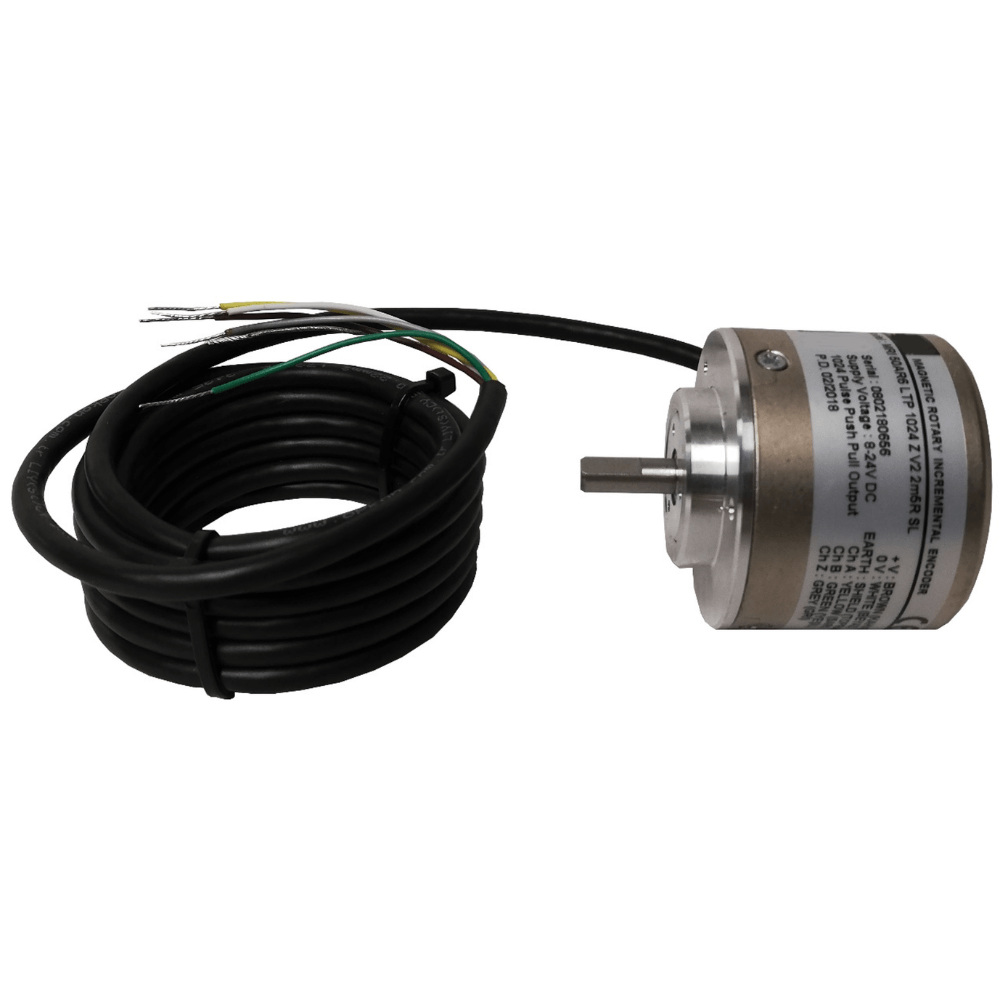

TECHNICAL FEATURES

[ LAP PULSES: 1024 ]

→ Output channel: Z

→ Output cable: R = Radial

→ Output type: LTP = Push-Pull

→ Max. speed: 3500 rpm

→ Shaft diameter: Ø6 mm

→ Housing diameter: Ø50 mm

→ Connector/cable length: 2M5 = 2,5m

→ Supply voltage: V2 = 8-24V DC