TO MANAGE THE PROCESSING OF

HEAVY SHEET METAL AND LARGE SIZES

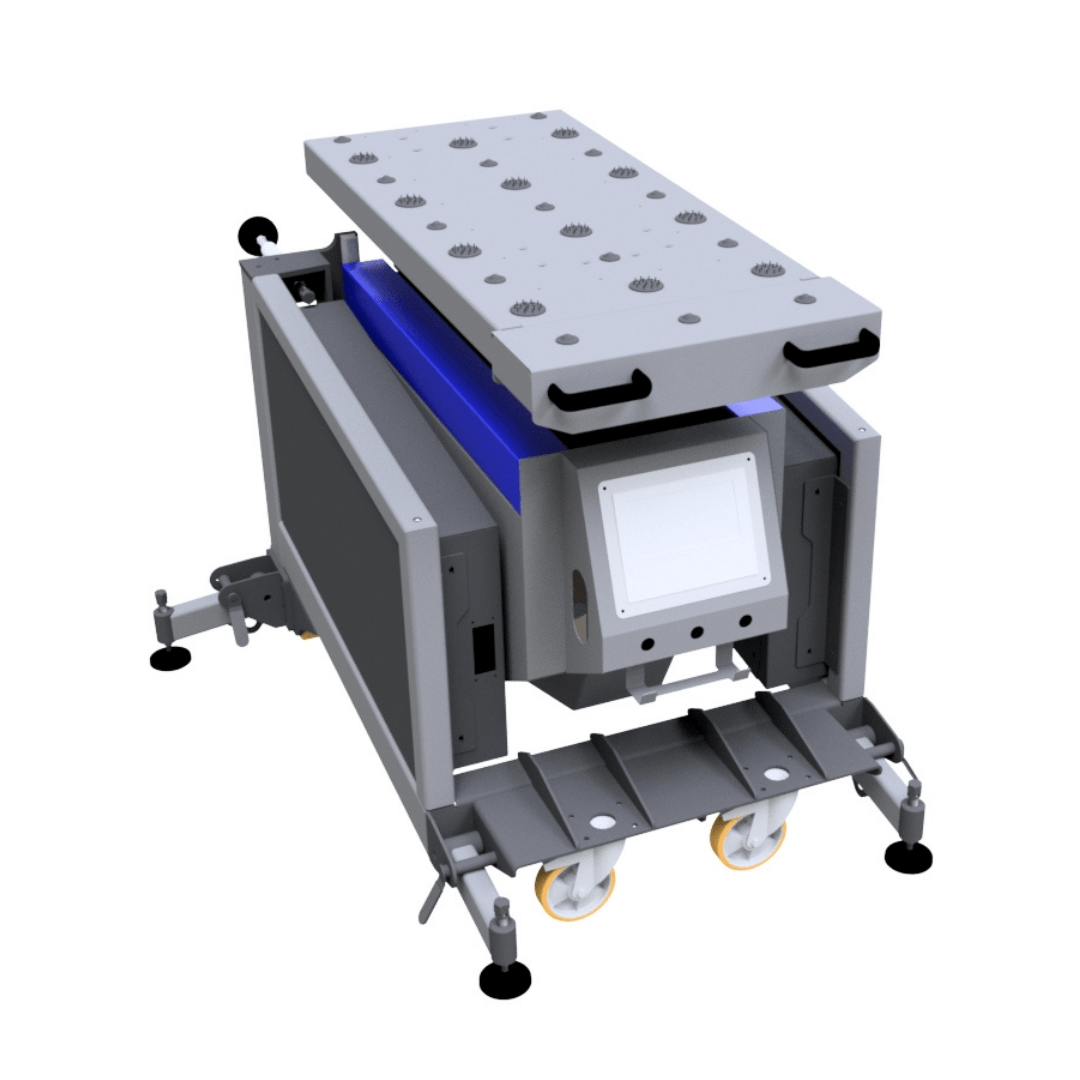

Up is an electric bending aid that you can install to any press brake and being a portable system, you can also use it by juxtaposing it with multiple press brakes in your same fleet depending on your processing needs.

The UP 300 FULL W model of sheet metal follower provides:

- maximum door equal to 150kg

- manual handling by trolley

- complete with parking feet

- motorized vertical and horizontal handling

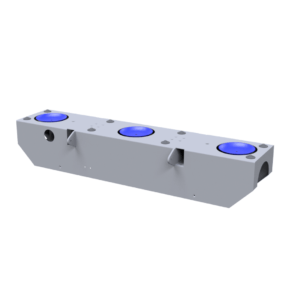

- provision for KIT VACUUM for unparalleled control and safety

- see more features and dimensions of UP 300 FULL W in the TECHNICAL DATA SHEET

Up, as a bending aidt, can greatly improve the bending process in cases where parts of considerable weight and size have to be handled, as:

- Increase SAFETY

UP is an added device that follows the sheet metal to be processed and is able to eliminate all the risks for the operator.

- Improve PERFORMANCE

The bending aid UP 300 FULL W can be configured with additional accessories to further enhance its use.

-> Discover the optional extras applicable to this version of UP by consulting the CONFIGURATOR

THE REVOLUTIONARY SHEET METAL BENDING AID

How can the bending operation of large-sized sheet metal be facilitated? And how can workers operating the machine be protected from injuries risks? These are the questions we asked ourselves when designing UP.

In the sheet metal bending sector, technological innovation is crucial to improve efficiency and operational safety.

The most significant problem that arises during the bending phase at the press brake is the need to manually support and handle the worked metal piece, which is often very heavy and large.

UP is a sheet metal follower device that helps the operator during the bending phase, bringing numerous benefits and advantages both for the operator and for the productivity.

ADVANTAGES AND BENEFITS FOR UP USERS: FROM SAFETY TO PERFORMANCE

Using the electric bending aid UP offers numerous advantages.

First of all, it significantly reduces operator fatigue, allowing him to keep an ergonomic posture and it significantly reduces the risk of injuries related to sheet metal lifting.

By improving the precision and speed of operations, UP consequently increases the overall productivity.

An operator aware of working safely, feels certainly more comfortable and can reach a higher production efficiency level.It is also well known that, working in a relaxed and comfortable atmosphere is fundamental to reduce the personnel turnover and it helps to maintain a cohesive, happy and motivated team.

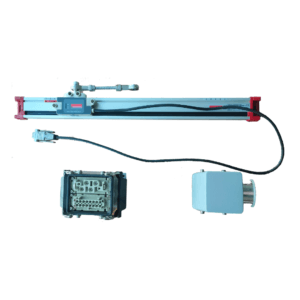

Another remarkable benefit is the versatility of our UP sheet follower devices, which can be applied to press brakes of different generations, including those with older numerical control (CNC). In fact, UP is equipped with an own electronic CNC independent lifting system that does not require complex integrations with the existing machine control.

Here are the 3 versions of UP designed for different needs and requirements.

DIFFERENCES BETWEEN UP BASIC, FULL AND ON

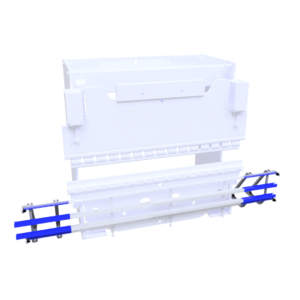

- Model UP 300 BASIC W: This model can be positioned in front of the press brake when needed, thanks to the wheels that make it easily transportable.

Its characteristics of being moved according to the working needs, makes UP BASIC ideal for workshops with occasional movement needs and variable workspaces. - Model UP 300 FULL W: beyond being portable, this version offers automatic motions. This feature allows to perform a precise bending cycle, adapting the various phases of the process without the operator intervention.

It is the perfect choice for high-intensity production requirements where efficiency and automation are crucial. - Model UP 300 ON: it is integrated directly on the press brake, this model represents the most advanced solution. This integration allows a synchronized working operation with the machine, ensuring a continuous and uninterrupted support throughout the bending cycle.

It is ideal for plants with high production targets and the need of a maximum precision.

The UP range is designed to be employed also in tandem configuration, allowing to support very heavy and bulky metal sheets, such as those in the automotive and metalworking branch.

MANUAL, ASSISTANCE, AND SYSTEM INTEGRATORS

One of the most significant hurdles during the bending activity is the production halt that occurs when a problem arises, especially in terms of lifting.

UP immediately solves the production halt, as it is tested and well performing even in the case of anomalies, thanks to its guaranteed immediate assistance. All models are supplied with a detailed use and maintenance manual and can be connected to an assistance service via a network cable for immediate diagnostics.

Our mission is to make this production process, an essential habit. Triveneta Impianti is, in fact, looking for System Integrators: i.e. Professionals who can sell, install and distribute these innovative products in the territory.

Offering immediate, continuous and worldwide support is essential to provide excellent service to our clients and to allow all involved to work safely and achieve better results.

JUST CHOOSE YOUR UP

Sheet metal electric bending aid is a revolution in the bending process, offering advantages in terms of safety, efficiency, and precision.

Thanks to the different models and the possibility of integration with old generation machines, UP is a versatile and indispensable solution for improving productivity and work quality.

If you are interested in exploring these opportunities, contact us to learn more and discover how UP can elevate your business.