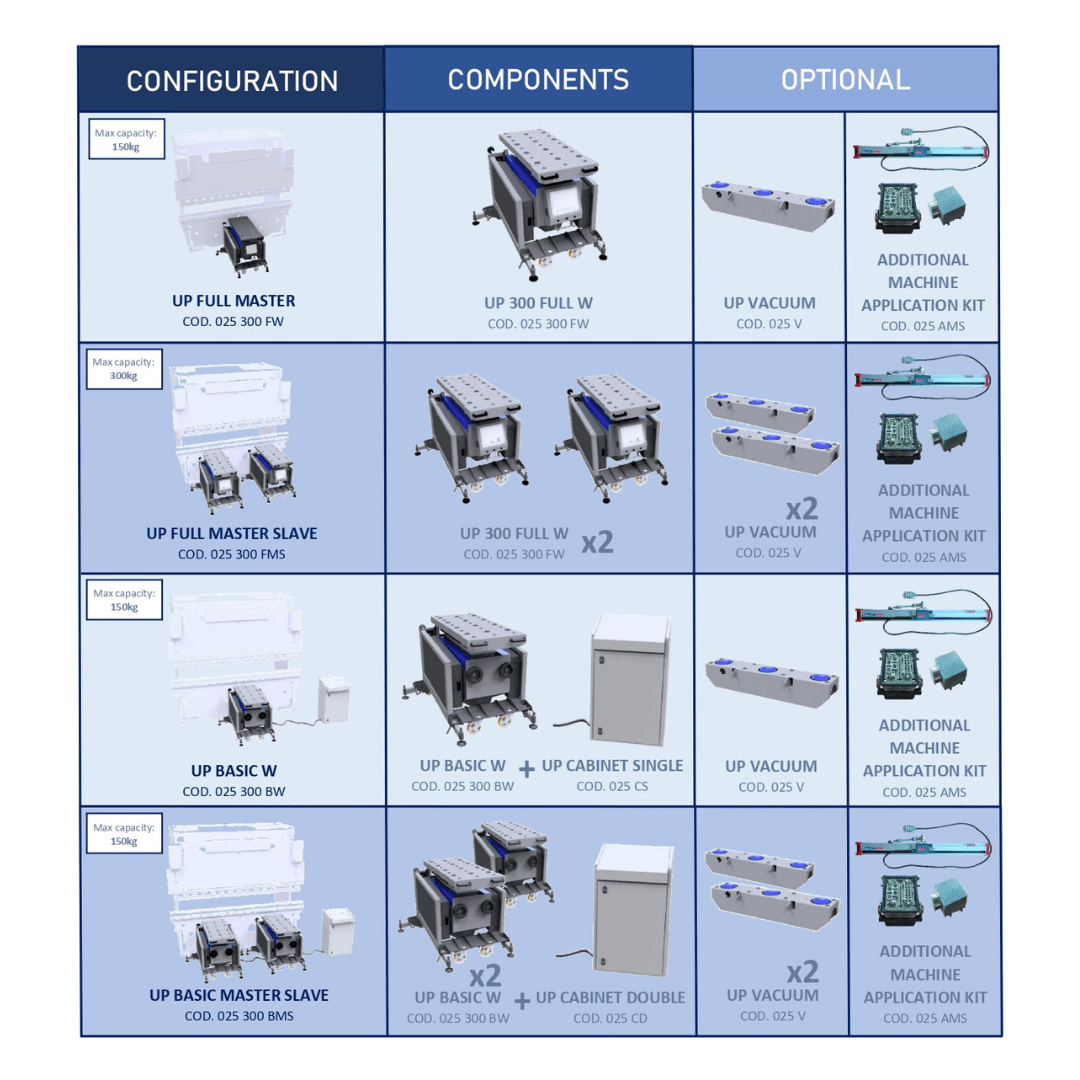

Each model of the electric bending aid UP for heavy and large sheets can be requested in different configurations and can be equipped with different accessories.

Mainly according to the maximum capacity (150kg or 300kg) you need to have in your company for your workings you can choose whether to take advantage of the option of installing a single UP or the double MASTER-SLAVE configuration.

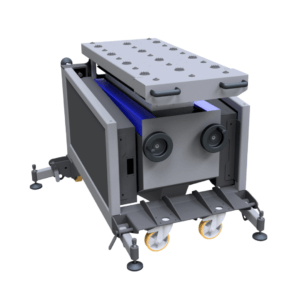

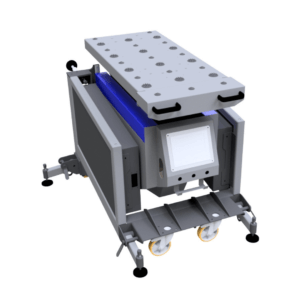

The main feature of the MASTER version of UP is that it is a sheet metal follower that can operate as a single device independently or as the main of a second lift – its subordinate – SLAVE model.

Hence, the SLAVE version of UP has as its main characteristic to be a bending aid that can operate only as a second sheet metal follower to be juxtaposed with UP model MASTER as its subordinate, since it is possible to install on the same press brake two UPs -one Master and one SLAVE – to make them work in tandem.

Other options and accessories to implement the user experience during processing:

- UP VACUUM

This is a kit of three suction cups with a capacity of 30kg/cad. that can be applied to any model, allowing for maximum control of the workpiece and adding additional safety to the sheet metal lifting phase. - ADDITIONAL MACHINE APPLICATION KIT

Because the UP 300 FULL W and UP 300 BASIC W sheet metal escorts are transportable and therefore applicable to multiple press brakes in the company’s fleet, this kit is specially designed to facilitate UP operation when the latter needs to be connected to multiple machines. - UP RAIL

Indispensable for direct application to the front of the press brake in the case of the choice of a bending aid UP 300 ON, it allows the movement of this on “rails” arranged along the length of the machine on which it is applied. - UP PARKING

Allows the UP 300 ON to be removed from the press brake by removing it from the UP RAIL and leave the sheet metal follower “parked” beside the machine tool to which it is applied (available in left and right versions depending on the side of the machine and the need to have a double UP PARKING if you have two UP ON – MASTER/SLAVE – applied to the same press brake).

See the configurator in the PRODUCT SHEET for full details.